Punch Press Servo Feed Machine

Basic Info

Model No.: RNC

Product Description

PUNCH PRESS SERVO FEED MACHINE

Punch Press Servo Feed machine is one of the popular servo feed machine in the market, It can feeds sheet metal coil material width up to 1300mm, thickness up to 6.0mm, with max. feeding speed 20m/min.

Operating with Computerize Numerical Control by PLC program from MITSUBISHI made in Japan, it can ensure +/-0.01mm high feeding precision.

Usually it matches with adjustment signal from the cutting machine or power press machine.

The feature of Punch Press Servo Feed Machine

1. Material Width:100-1500mm

2. Material Thickness: 0.2-3.2 mm.

3. It can feed material for various thickness and feeding stroke length.

4. It suits for high speed feeding, long stroke length feeding, to improve production capacity and feeding precision.

6. It adopts pneumatic cylinder releasing method, without malfunction.5. With a good operation panel, so users can input feeding length number, feeding speed number freely. Feeding length range is 0.1mm-9999.99mm.

7. Mechanical releasing method can be made according to customers` requirement.

8. A mounting plate can help the servo feeder install to press machine easily. Or you can choose a separate bracket for better stability.

The Structure of Punch Press Servo Feed Machine

1. It adopts high quality servo motor, so can shorten time of feeding testing efficiently.

2. It adopts high-sensitivity encoder, to ensure feedback and improve feeding precision.

3. It adopts good belt, to avoid gears gap, to avoid gear abrasion, without noise,

without lubrication, safe, environmental.

4. Motor is installed in its structure internally, to avoid possible damages caused during transportation and loading.

SPECIFICATION

| Punch Press Servo Feed Machine | |||||||

| Specifications | |||||||

| Model | RNC-200 | RNC-300 | RNC-400 | RNC-500 | RNC-600 | RNC-700 | RNC-800 |

| Coil Width | 200 mm | 300 mm | 400 mm | 500 mm | 600 mm | 700 mm | 800 mm |

| Strip Thickness | 0.2-3.2 mm | ||||||

| Release | Pneumatic Type Releasing System | ||||||

| Feed Roll | Upper Roll Ø65mm, Bottom Roll Ø80mm | ||||||

| Feed Length | Max. 9999.99 mm | ||||||

| Speed | Max. 20m/min | ||||||

| Accuracy | ± 0.01 mm | ||||||

| Servo Motor | Yaskawa, Japan | ||||||

| Servo Drive | Yaskawa, Japan | ||||||

| PLC | Mitsubishi, Japan | ||||||

| Touch Screen | Weinview, Taiwan | ||||||

| Power | 0.85 Kw | 1.3 Kw | 1.8 Kw | 2.9 Kw | |||

APPLICATION

Metal Sheet Stamping line is widely used to LED Parts, automobile stamping, appliances manufacturing, computer and electronic componets, hardware and metal parts etc industry.

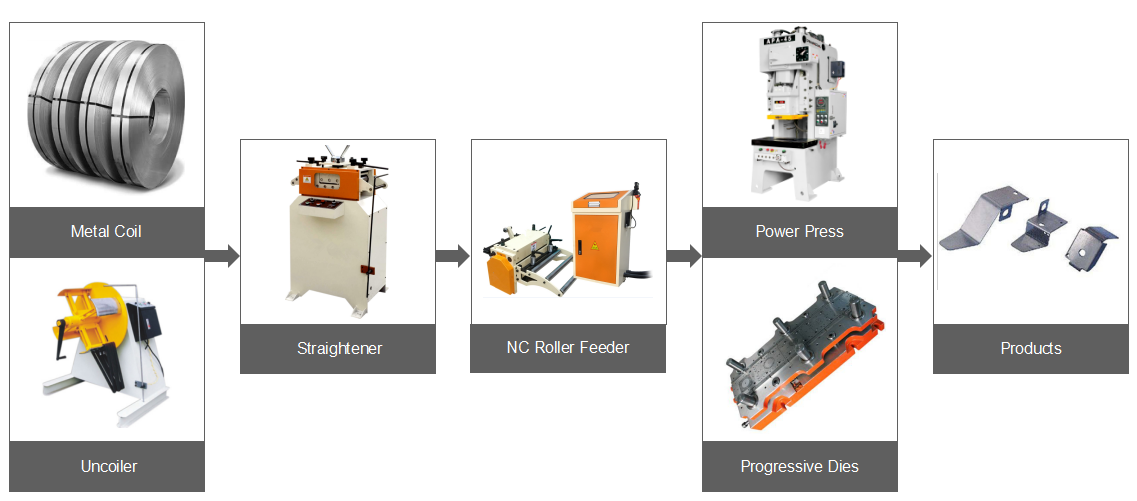

The configuration of metal sheet stamping line

Step-1: Decoiler machine, Loading coil and uncoilling coil.

Step-2: Metal Sheet Straightener machine, leveling the strips.

Step-3: NC Servo Roll Feeder machine, Feed coil to press machine.

Step-4: Power press machine with the moulds,pressing to the end product

The configuration of NC Servo metal Punch Press Feeder Stamping line

Step-1: Decoiler straightener machine, Loading coil and uncoilling coil and straigthening the Coil strips.

Step-2: NC Servo Roll Feeder machine, Feed coil strips to press machine.

Step-3: Power pres machine with the moulds,pressing to the end product

Punch Press Servo Feed Machine is testing in our workshop.

Product Categories : Press Feeders > Servo Roll Feeder