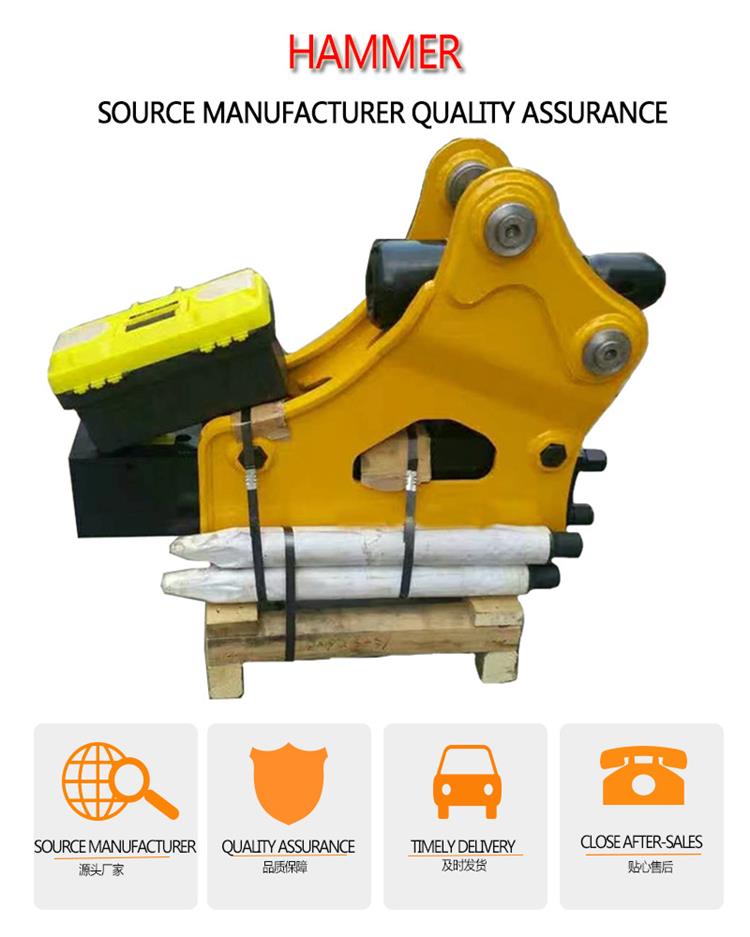

Excavator hydraulic hammer side type hydraulic breaker mini excavator jack hammer provide a variety of specifications and models

Product Description

Excavator hydraulic hammer side type hydraulic breaker mini excavator jack hammer provide a variety of specifications and models

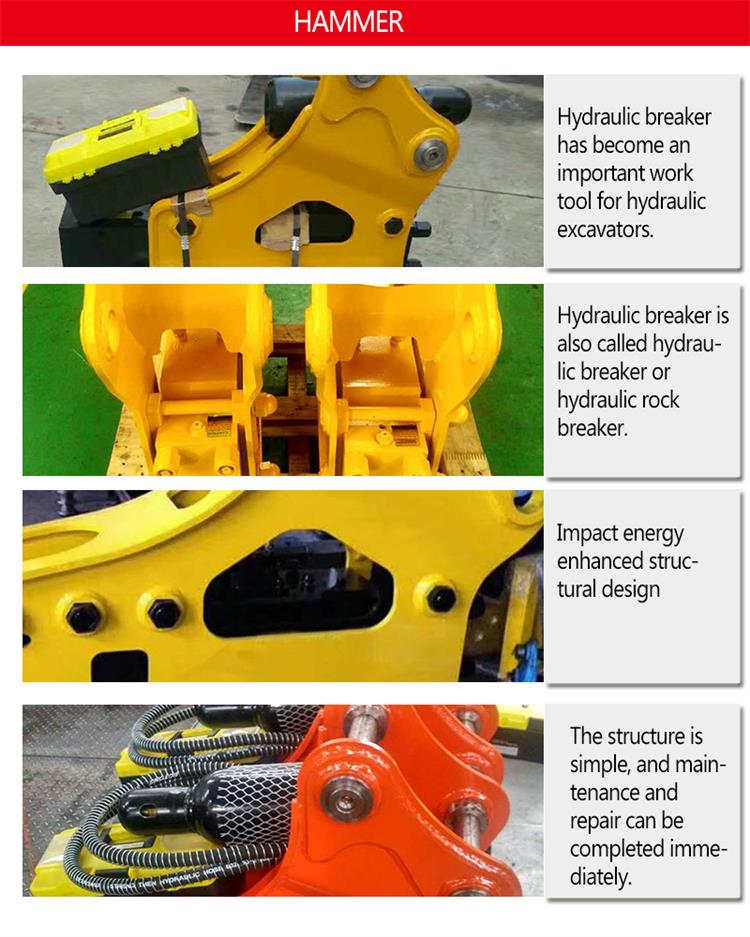

Breaker characteristics

Impact energy enhanced structural design

The hydraulic breaker adopts the optimized design concept, increases the stroke of the piston and cylinder, and adopts the same large diameter of the piston and drill rod, so that the breaker can match the main engine well, and the output energy is reasonably used, saving energy, and achieving work efficiency.

Use high-quality materials and special precision craftsmanship.

·Heat treatment technology: Enhance heat resistance and wear resistance.

·Low fuel consumption design: reduce the volume of the oil cylinder and reduce fuel consumption while ensuring the same oil pressure.

·Durability design of the movement: the piston ring oil passage design is adopted to reduce resistance and make the piston cylinder more durable. Through the design of reduced rebound force, it protects the movement and has a longer service life.

·Durability design of deck: The exposed deck adopts high-strength steel plate to reduce the degree of wear.

·Durability design of oil seal: add oil return channel design on the pressed surface of the oil seal to reduce the pressure of the oil seal and increase the service life of the oil seal.

·Lightweight design: Realize the best performance matching with excavators and loaders.

·Low-noise design: In urban areas with noise restrictions, the noise can be effectively reduced through shock-absorbing rubber pads and sealed boxes. Low-noise bracket breakers can be used.

The power source of the breaker is the pressure oil provided by the pumping station of the excavator or the loader, which can effectively clean the floating stones and the soil in the cracks of the rock in the role of excavating the foundation of the building. The principle of selecting a hydraulic breaker is to select a suitable hydraulic breaker according to the model of the excavator and the operating environment. The hydraulic breaker has become an important work tool for hydraulic excavators. Some people also install the hydraulic breaker on the backhoe loader (also known as busy at both ends) or wheel loader for crushing operations. Hydraulic breaker is also called hydraulic breaker or hydraulic rock breaker.

How to use the breaker

1) Read the operating manual of the hydraulic breaker carefully to prevent damage to the hydraulic breaker and excavator, and operate them effectively.

2) Before operation, check whether the bolts and connectors are loose, and whether there is leakage in the hydraulic pipeline.

3) Do not peck holes in hard rocks with hydraulic breakers.

4) Do not operate the breaker with the piston rod of the hydraulic cylinder fully extended or fully retracted.

5) When the hydraulic hose vibrates violently, stop the operation of the breaker and check the pressure of the accumulator.

6) Prevent interference between the boom of the excavator and the drill bit of the breaker.

7) Except for the drill bit, do not immerse the breaker in water.

8) Do not use the breaker as a lifting device.

9) Do not operate the breaker on the crawler side of the excavator.

10) When the hydraulic breaker is installed and connected with the hydraulic excavator or other Construction machinery, the working pressure and flow rate of the main engine hydraulic system must meet the technical parameter requirements of the hydraulic breaker. The "P" port of the hydraulic breaker is connected to the main engine high-pressure oil circuit Connect, "A" port is connected with the return line of the main engine.

11) The best hydraulic oil temperature when the hydraulic breaker is working is 50-60 degrees, and the height should not exceed 80 degrees. Otherwise, the load of the hydraulic breaker should be reduced.

12) The working medium used by the hydraulic breaker can usually be the same as the oil used in the main hydraulic system. It is recommended to use YB-N46 or YB-N68 anti-wear hydraulic oil in general areas, and YC-N46 or YC-N68 low temperature hydraulic oil in cold areas. The filtration accuracy of hydraulic oil is not less than 50 micro; m.

13) The new and repaired hydraulic breaker must be refilled with nitrogen when it is started, and its pressure is 2.5, ±0.5MPa.

14) Calcium-based grease or compound calcium-based grease must be used for lubrication between the handle of the drill rod and the guide sleeve of the cylinder block, and it should be added once per shift.

15) When the hydraulic breaker is working, the drill rod must be pressed on the rock first, and the breaker must be operated after maintaining a certain pressure. It is not allowed to start in the suspended state.

16) It is not allowed to use the hydraulic breaker as a crowbar to avoid breaking the drill rod.

17) When in use, the hydraulic breaker and the fiber rod should be perpendicular to the working surface, based on the principle that no radial force is generated.

18) When the broken object has cracked or started to produce cracks, the impact of the breaking hammer should be stopped immediately to avoid harmful "empty hits".

19) If the hydraulic breaker is to be stopped for a long time, the nitrogen should be exhausted, the oil inlet and outlet should be sealed, and the cut iron should be stored under high temperature and below -20 degrees.

Color: can be customized

Model: multiple models and specifications

Drill rod diameter: 35mm

Body weight (incl. chisel)kg:2663

Total weight kg:4841

Size (L*W*H) mm:3420*764*1635

Hydraulic oil flow l/min:220~290

Hydraulic pressure kg/cm2:200~240

Blow frequency bmp:180~200

Chisel diameter mm:195

Carrier weight ton:45~60

FAQ

1: What kind terms of payment can be accepted?

A: For terms of payment, L/C, T/T, D/A, D/P, Western Union (can be) could accepted

2: What certificates are available in Machinery?

A: For the certificate, we have CE, ISO,EPA(USA),CCC

3: What about the delivery time?

A: 7-20 days after receiving the deposit.

4: What about the warranty time?

A: 12 months after shipment or 2000 working hours, whichever occuts first.

5. What about the Minimum Order Quantity?

A: The MOQ is 1 pcs

6.What about the service?

1). Quick response to every inquiry.

2). Professtional and detailed answer to any of customer's questions.

3). Strict QC and in time delivery.

4). Offer all relative material for customer to know and better use the machine.

5). Periodically after service follow up, offer any necessary support if needed.

6).For the new machine, within determined limits, the manufacture guarantees warranty for a period of 12 months after bought or 2000 working hours(whichever comes first).

7).The warranty includes repairation or replace the Parts for free which were proved to be defective in origin by the technical department of the manufacture.

8).The repairation or replacement for the parts should not exceed the warranty period.

9).The warranty is valid on the condition of all the terms listed in the contract was observed.

Product Categories : Construction machinery

Premium Related Products